Device version

Trouble improvement of existing equipment

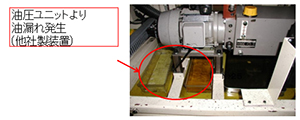

"Troubles of existing devices that became obsolete"

It is troubled that the trouble of the device can not be solved because the original manufacturer can not deal with it, or the manufacturer is lost.

![]()

"Supported by NFT"

Since there are many parts manufacturing and repairing results of other company's equipment, we can cooperate with troubleshooting. When trouble occurs, equipment confirmation, meetings will be handled even at the site.

Automatic release shot

"Frequent demolding recovery shots are necessary and productivity is bad"

It is necessary to stop the machine each time and manually perform mold release recovery shots. I want to improve production efficiency.

![]()

"Automatic mold release recovery shot function added to NFT made auto mold machine"

Automatic release recovery shot was executed at an arbitrary frequency during production, and we succeeded in significantly improving productivity.

<Example of Productivity UP>

* When shotting 1 shot is required for 20 shot = 1 h

a) Before improvement (manual release shot)

6 minutes / release shot + OP (person) + back and forth stop time 4 minutes = 10 minutes

20 shot / 70 min = 17 shot / h

b) After improvement (auto release shot)

3 minutes / release shot + (OP unnecessary) + (no back and forth stop time) = 3 minutes

20 shot / 63 min = 19 shot / h

Productivity improvement by automating release agent spraying operation

"I want to automate manual molding / release agent spraying"

Product under production must spray the release agent. Moreover, in order to prevent uneven spraying, it has to be sprayed with the hand of man, necessarily one press / one person is necessary and efficiency is bad. Automation of molding equipment is indispensable in order to carry out production efficiency UP and labor cost reduction at the same time.

![]()

"Developing equipment equipped with automatic release agent spraying mechanism"

By mounting a spray nozzle, it is possible to apply release agent in a series of molding cycles. The tip nozzle also adopts liquid sagging and liquid clogging prevention specification, greatly improving maintainability. Productivity increases by 10% per year against existing manual press.

※ Applied to productivity improvement facility promotion tax system

Release agent spray mechanism

Release agent spray mechanism

Productivity improvement through automated molding process

Productivity comparison

Existing equipment: Across M - 60 (manual press)

| Cure time: sec | Injection time: sec | Manual time: sec * 1 | Total cycle time: sec | Production volume per hour / 1 Press |

| 180 | 24 | 60 | 264 | 27.2 sheets / hour |

※ 1 It becomes customer measurement time worked by manually setting board, frame set, release agent spray coating, molded product removal all.

![]()

21% Productivity improvement

The latest equipment: Across 2 by 2 - 120 and Across 2 by 3 - 60 (auto mold press)

| Cure time: sec | Injection time: sec | Machine time: sec | Total cycle time: sec | Production volume per hour / 1 Press |

| 180 | 24 | 15 | 219 | 32.8 sheets / hour |

Supplement

As for products requiring releasing agent, we were able to comply with AcrossM (manual press) only because we were spraying (releasing) release agent coating on existing equipment, but by installing automatic spray mechanism Automatic Multiple press making becomes possible and the total cycle time is shortened by 45 seconds.

Regarding the Across 2 by X series above, in the case of Across 2 by 2, it is 2 press specifications, 66 sheets per hour (141% up), Across 2 by 3, 3 press specifications, 99 production per hour (263% up) I will.